Energy efficiency of lime brining

Practical Action

Some limestones are dolomitic, that is they contain

the mineral dolomite, CaCO3MgCO3, in addition to the

CaCO3 which is present as the mineral calcite.

Usually, pure calcitic limestones are preferable but

dolomite can be tolerated provided the quicklime is

well slaked before use.

Figure 1: A traditional lime kiln in

Sudan. Photo: Simon Croxton /

Practical Action

Efficiency of lime burning

Lime burners are generally seeking to produce the

highest quality quicklime possible from their stone

whilst keeping their production costs to a minimum. In

the majority of cases, a very major production cost will

be the fuel used. Thus, the efficiency of the burning

process (as opposed to the whole process of production

which will involve labour costs etc.) is judged by how

much fuel it takes to produce a quantity of quicklime.

For instance, a lime-burner may say “I produced X

tonnes of quicklime using Y tonnes of coal which cost

me Z dollars”. However, in order to compare different

types of kilns using various fuels and producing

quicklime of variable quality, it is necessary to develop

a more universal measure of efficiency.

Kiln or burning efficiency can be determined and

compared using the formula for thermal efficiency

proposed by Robert Boynton, former director of the

National Lime Association in the USA, in his book

‘Chemistry and Technology of Lime and Limestone’:

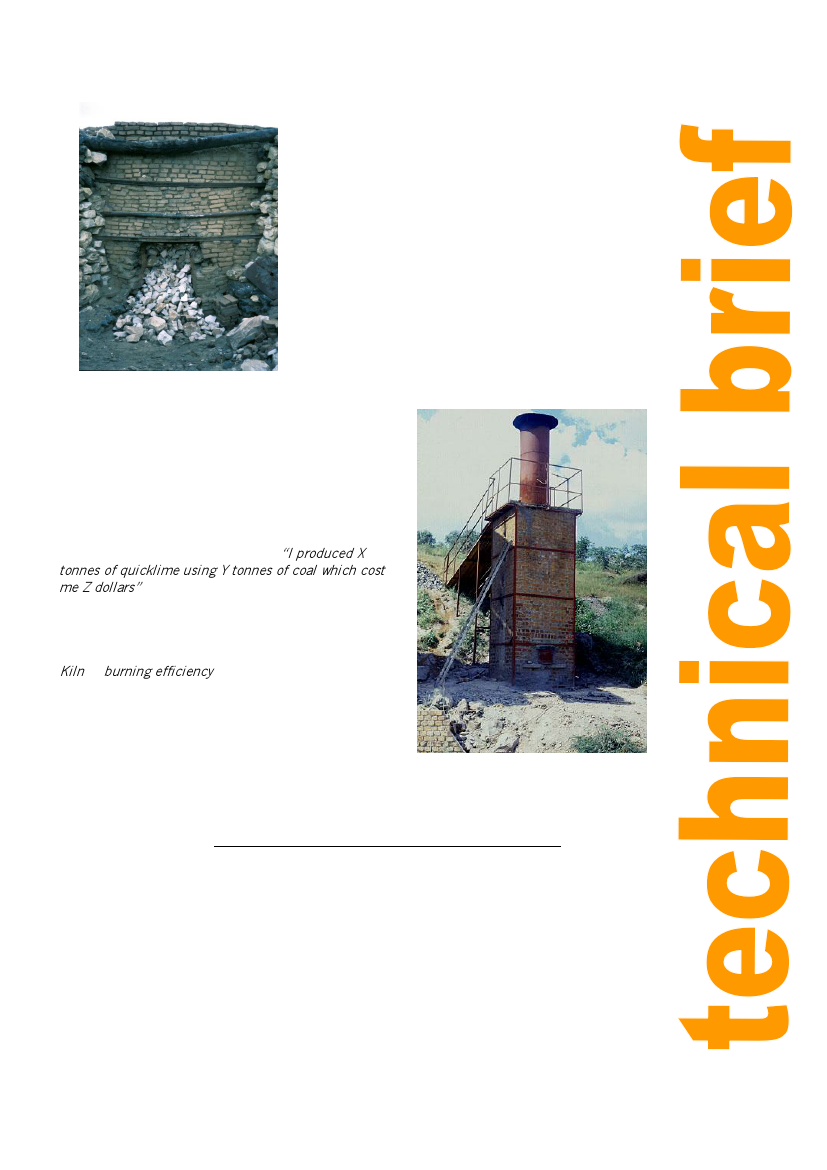

Figure 2: An improved vertical shaft kiln in

Zimbabwe. Photo: Kelvin Mason / Practical

Action.

Thermal efficiency (%) = theoretical heat requirement x available oxide content(%)

total heat requirement

2